-

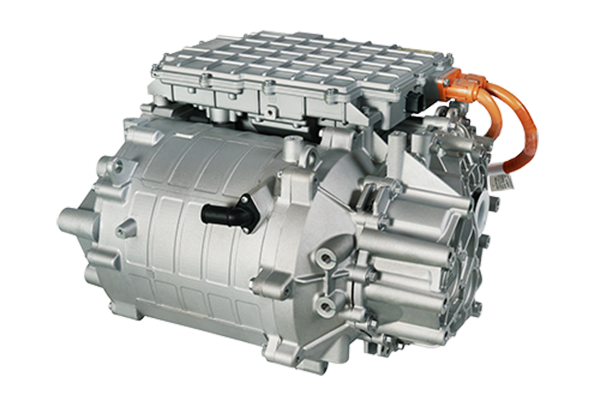

High, small, light, low

Motor, reducer and controller are highly integrated, motor and reducer common end cover, smaller volume. The stator end is short, the copper consumption is lower, the overall weight is lighter.

-

High power density and torque density

Flat copper wire three-phase permanent magnet synchronous motor, hair card type bronze layout, higher slot full rate, low groove torque and torque ripple, motor efficiency is higher. Single solder joint, reduce winding hot spot

-

Excellent heat dissipation performance

The internal structure of the motor design is more compact, the contact area between the flat copper wire is large, the winding and the iron core groove contact is better, and the heat dissipation area is increased. Can choose water cooling or oil cooling two cooling methods, cooling efficiency is higher.

-

Low noise

Flat wire motor wire stress, armature stiffness is better, can effectively suppress armature noise.

Notch size is small, reduce groove torque, further reduce motor noise.

-

Flexible customization

The power module of the controller can be SiC or double-sided water-cooled package module, HPD module, power module 820A or 950A IGBT optional.

Reducer (P gear optional) a variety of different speed ratios can be selected, shaft tooth NVH effect to reach the industry advanced level.

-

Class 3+ on-load EMC

Equipped with Class 3+ on-load EMC, excellent anti-interference performance.

WeChat

WeChat